test 001

- Home

- Product Search

- test 001

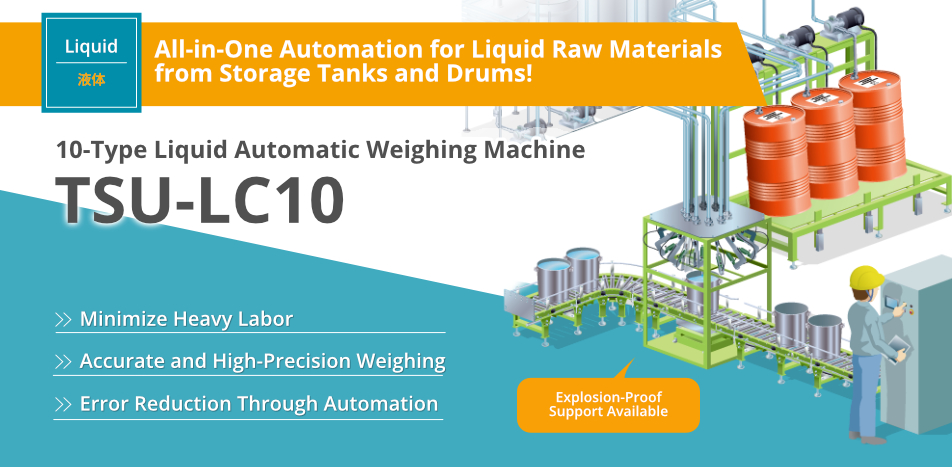

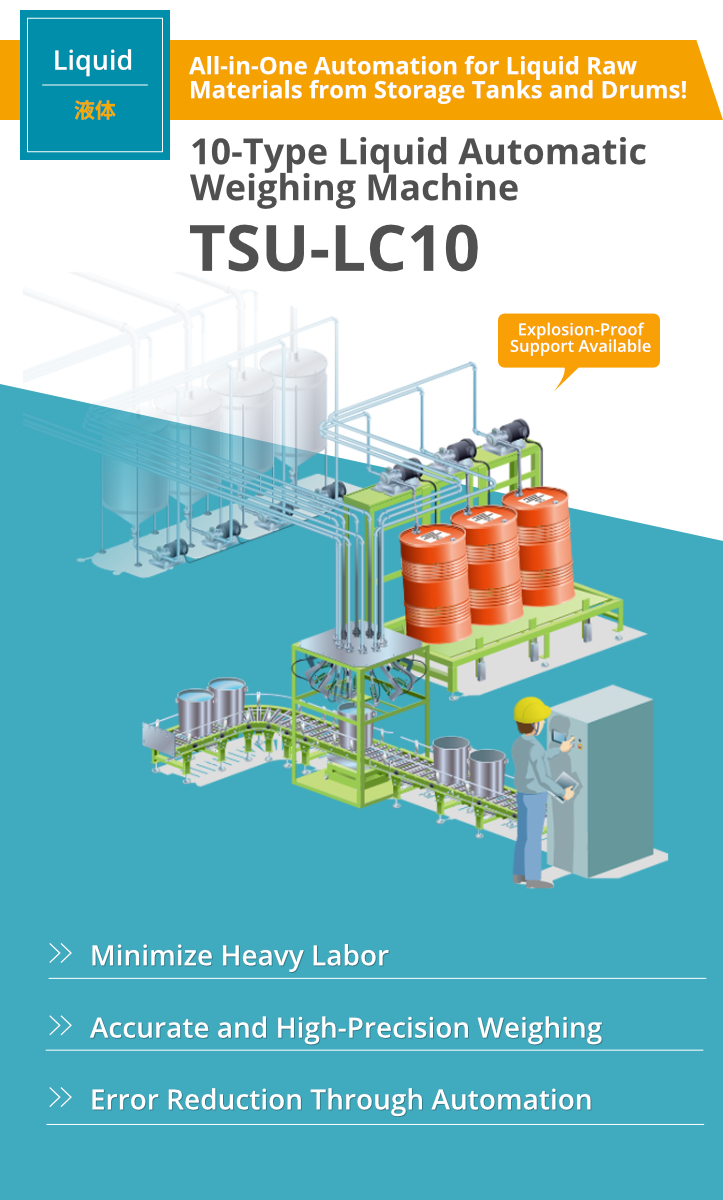

What is “TSU-LC10”?

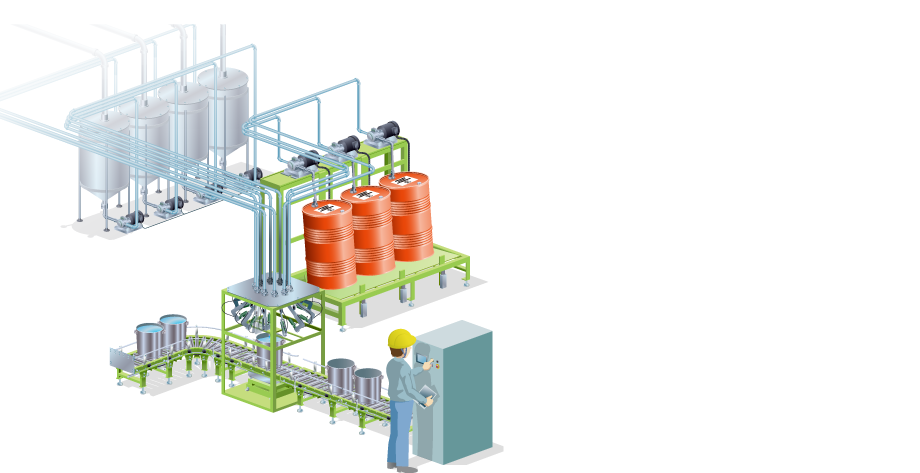

A single weighing machine can automate liquid raw materials in storage tanks or drums.

The swing arm filling nozzle enables labor saving and reduces weighing errors in limited spaces.

3 Point Improvements Achieved by “TSU-LC10”

Labor Saving

Minimize

Heavy Labor

High Speed &

High Precision

Accurate and

High-Precision

Weighing

Weighing Error

Reduction

Error Reduction

Through Automation

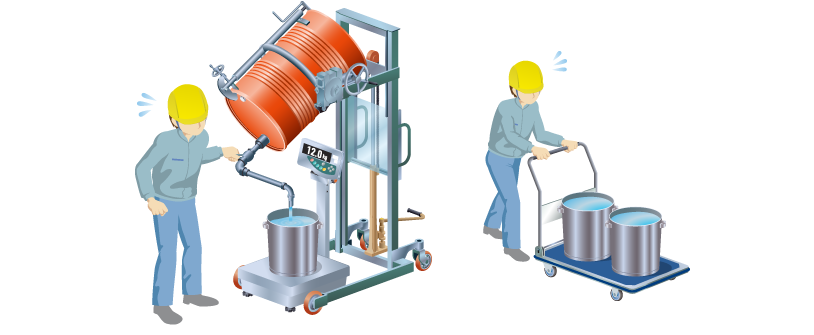

Effects of Implementation (Before▶After)

It is possible to automatically perform weighing according to the mixing recipe, instead of the conventional manual weighing.Simply select a pre-registered mixing recipe and enter the production quantity (number of batches) to complete the process.The remaining time can be used for other tasks, creating an efficient working environment.

Before

Manual Weighing

After

Automatic Weighing

Easy Operation

Simply enter the production quantity (number of batches)

to complete!

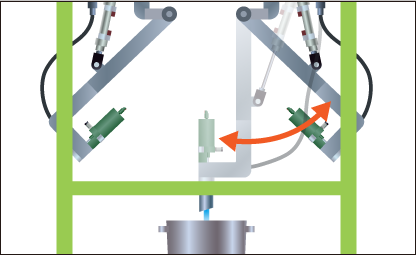

Space-Saving Design

Space-Saving Design

The arm for weighing raw materials moves to the center of the weighing container and fills it, allowing for weighing in containers of various sizes.

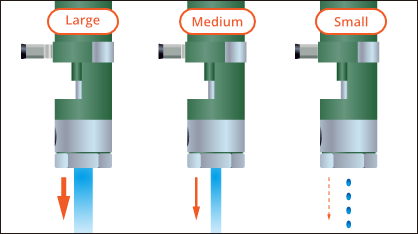

3-Tier Filling Nozzle

3-Tier Filling Nozzle

Three-Stage Switching System (Large, Medium, Small) Achieves High Speed and High Precision.

Specifications Automatic Weighing from 100g to 20kg is Possible!

| Raw Material Type | 10 Types (Liquids Transported from Indoor/Outdoor Storage Tanks or Drums via Piping) |

|---|---|

| Accessories | Supply Device Mounting Arm (Swing Type), Flexible Hose for Liquid Transfer, etc. |

| Supply Device | Variable Flow Valve (Three-Stage Switching System: Large, Medium, Small) × 10 Units |

| Supply Capacity | 200 kg/h (At a Temperature of 20°C, Water, Viscosity ≈ 1 cps, Specific Gravity 1.0) |

| Weighing Machine | 30 kg Electronic Platform Scale (Minimum Display 0.1 g) |

| Weighing Accuracy | ±1% of Set Value (※Depends on Powder Material Properties) |

| Weighing Unit Section | 1100W × 1100D × 1700H mm (※Reference Value: Depends on Equipment Specifications) |

We have a proven track record of automating up to 25 types.

We also support customized designs tailored to raw materials,

viscosity, specific gravity, and other required specifications.

Contact us to inquire about products here.

Please feel free to contact us for a consultation!

Hakaru Plus (Thailand) Co.,Ltd.

Monday to Friday 8:30-17:30