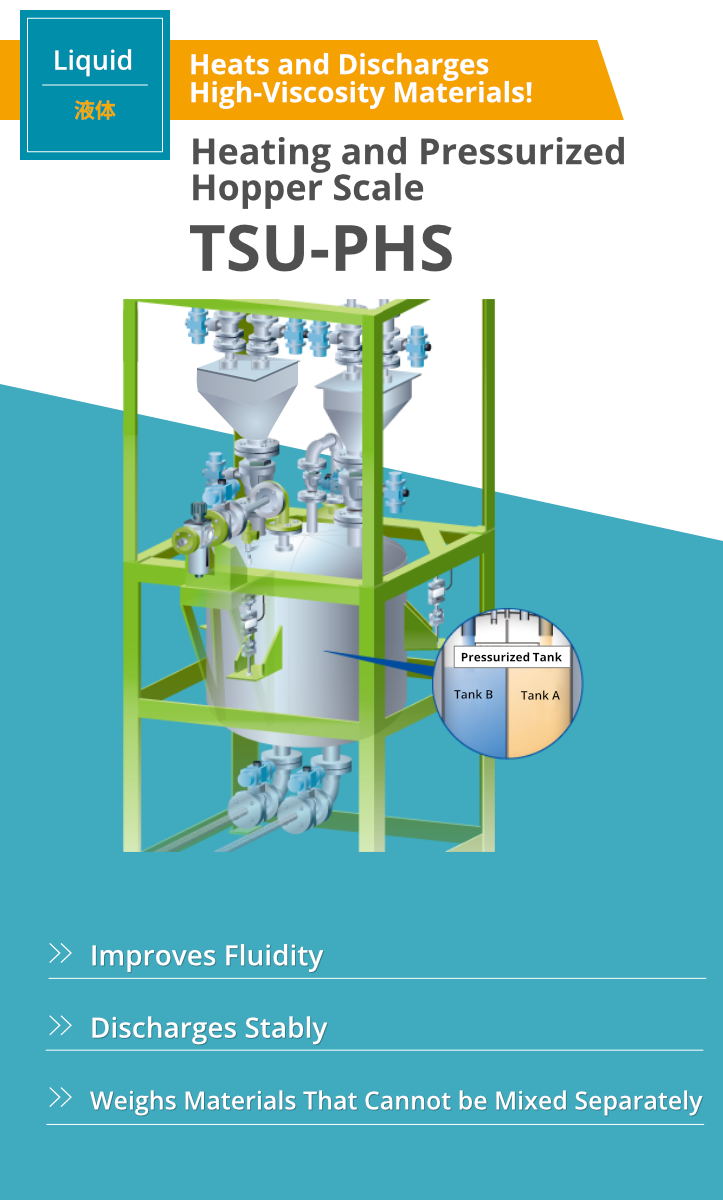

Heating and Pressurized Hopper Scale TSU-PHS

- Home

- Product Search

- Automatic Liquid Weighing

- Heating and Pressurized Hopper Scale TSU-PHS

What is the Heating and Pressurized Hopper Scale “TSU-PHS”?

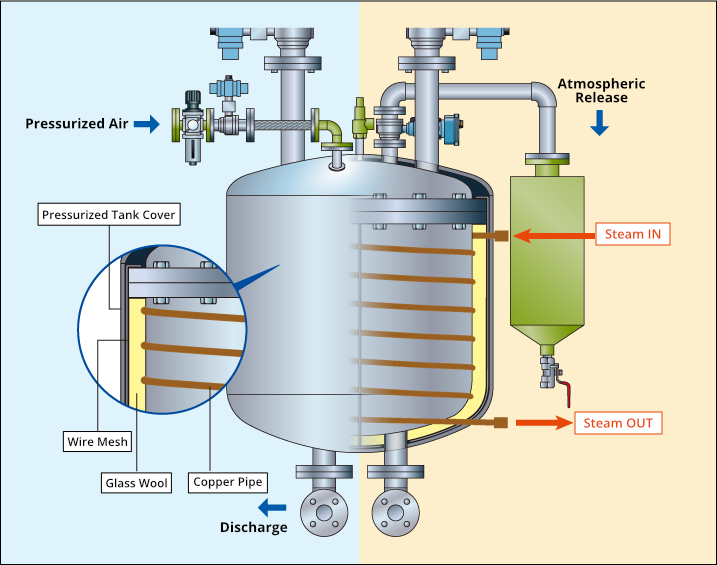

It heats high-viscosity raw materials to improve fluidity and discharges them stably while applying pressure.

With its two-tank structure, it is possible to weigh materials that you do not want to mix separately.

3 Point Improvements Achieved by “TSU-PHS”

Heating

Improves Fluidity

Pressurization

Discharges Stably

Two-Tank

Structure

Weighs Materials

Cannot be Mixed

Separately

Structure

Specifications

| Hopper Capacity | 50 L (Drained) x 2, Two-Tank Pressurized Tank |

|---|---|

| Hopper Material | SS400 (with Insulated Cover) |

| Accessories | Raw Material Supply/Pressurization/Atmospheric Release/Discharge Valve, Safety Valve, Level Sensor, etc. |

| Material to be Weighed | Liquid Raw Material (Viscosity During Heating Depends on Liquid Properties) |

| Weighing Machine | Load Cell Type 30 kg (Minimum Display 20 g) |

| Equipment Size | 1000W × 1000D × 2300H mm (※Reference Value: Depends on Equipment Specifications) |

We Support Customization Tailored

to Customer Specifications to Accommodate a Variety of Liquids

Contact us to inquire about products here.

Please feel free to contact us for a consultation!

Hakaru Plus (Thailand) Co.,Ltd.

Monday to Friday 8:30-17:30